In the world of medical devices, precision and visibility are critical. Radiopaque polymers play a vital role in making devices like catheters clearly visible under x-rays, helping guide medical professionals during complex procedures. ICP DAS-BMP offers cutting-edge radiopaque thermoplastic polyurethane (TPU) that enhances device performance without compromising mechanical integrity.

What Are Radiopaque Polymers?

Radiopaque polymers in medical devices provide contrast during X-ray monitoring, allowing precise location of the catheter tip and shaft as it moves through the patient’s body during a medical procedure. These materials contain fillers—known as radiopacifiers—that block or absorb x-rays, making the devices highly visible during medical procedures or when implanted into the body. The type and amount of radiopacifier used can be tailored to suit specific applications, ensuring the perfect balance between visibility and mechanical properties.

Devices designed for deeper body applications, such as coronary catheters, require higher levels of radiopaque fillers compared to devices used closer to the surface. Similarly, thin-walled tubing demands greater filler loading than thicker components. With precise customization, radiopaque polymers offer flexibility to meet a wide range of medical needs.

Key Radiopaque Fillers

1. Barium Sulfate

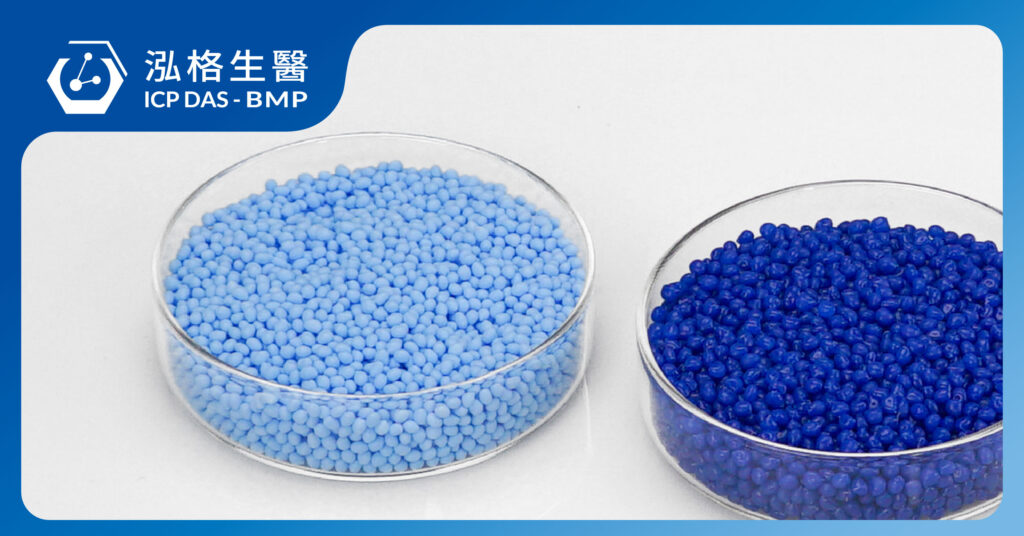

Widely recognized as a reliable radiopacifier, barium sulfate is often used in medical polymers due to its effectiveness and versatility. Its high performance is complemented by its ability to be color-matched for various design requirements. ICP DAS-BMP provides TPU formulations with barium sulfate loadings of 20%, 30%, and 40%, offering solutions that cater to diverse device specifications.

2. Tungsten

Known for its exceptional density and radiopacity, tungsten is an ideal choice for applications requiring strong x-ray shielding with minimal filler content. This is especially beneficial for thin-walled devices where maintaining mechanical properties is essential. ICP DAS-BMP’s tungsten-filled TPUs range from 30% to 80% tungsten content, delivering superior performance for the most demanding medical applications.

Why Choose ICP DAS-BMP?

ICP DAS-BMP is at the forefront of medical-grade TPU innovation. Our advanced radiopaque formulations provide unparalleled quality, helping manufacturers meet stringent industry requirements. Whether your goal is enhanced image contrast, improved mechanical properties, or precise customization, our team works closely with you to develop solutions that exceed expectations.

Conclusion

Radiopaque polymers are integral to the success of modern medical devices, offering the visibility and performance required in critical procedures. By choosing ICP DAS-BMP, manufacturers gain access to highly customizable materials designed for optimal x-ray contrast, mechanical strength, and durability.

Whether you need barium sulfate or tungsten-filled formulations, our radiopaque TPUs enable the creation of innovative medical devices that inspire confidence in both manufacturers and healthcare professionals. Trust ICP DAS-BMP to elevate your medical solutions to new levels of precision and reliability.

Leave a Reply